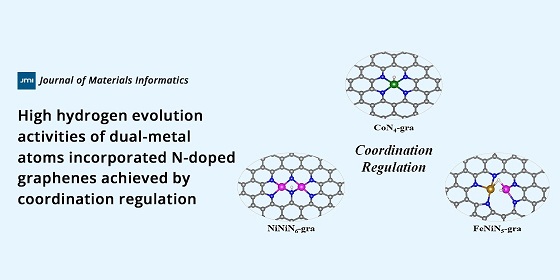

Journal of Materials Informatics

Views: Downloads:

Views: Downloads:

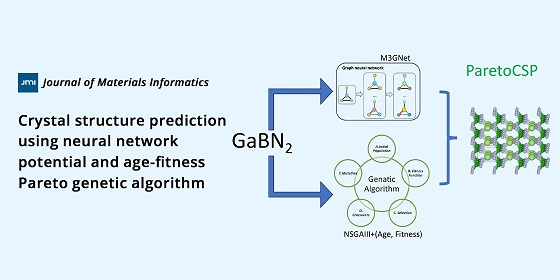

Crystal structure prediction using neural network potential and age-fitness Pareto genetic algorithm

Views: Downloads:

Views: Downloads:

Views: Downloads:

Views: Downloads:

Views: Downloads:

Views: Downloads:

Data

316

Authors

262

Reviewers

2021

Published Since

100,824

Article Views

39,744

Article Downloads

For Reviewers

For Readers

Add your e-mail address to receive forthcoming Issues of this journal:

Themed Collections

Related Journals

Related Journals

Data

316

Authors

262

Reviewers

2021

Published Since

100,824

Article Views

39,744

Article Downloads